Back to selection

Project

Skybrokers installed an used VertexRSI 9.0m Earth Station Antenna at broadcast provider ViewSat at the Cobbett Hill Earth Station in Guildford in the UK

Year

2013

Country

Client

ViewSat

Skybrokers installed an used VertexRSI 9.0m Earth Station Antenna at broadcast provider ViewSat at the Cobbett Hill Earth Station in Guildford in the UK.

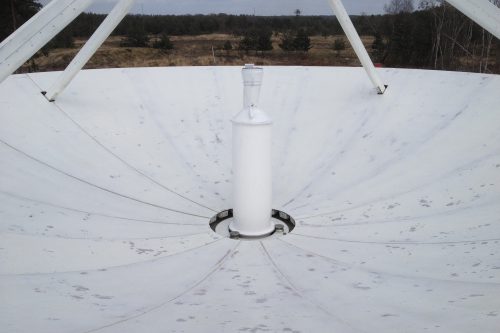

Skybrokers installed an used VertexRSI 9.0m Earth Station Antenna. Skybrokers secured a contract with ViewSat to deliver and install a VertexRSI 9.0m Earth Station Antenna at their premises co-located at the Cobbett Hill Earth Station facility in Guildford in the UK. Our team installed and refurbished the antenna in four weeks in April 2013.

ViewSat was a niche provider, serving broadcast and transmission services into sub-Saharan Africa. The company started operations in 2006 as a global media content service provider with over 130 channels worldwide, maintaining a sustained investment in new network capacity and contemporary systems, all designed to benefit its users.

Viewsat’s extensive satellite and fibre network platforms provide a global communications hub to broadcast audio and visual content direct to homes, studios or cable head ends on every continent. In 2019 ViewSat changed its name to ViewMedia to reflect the expansion of its portfolio to service the requirements of broadcasters worldwide.

Project

Skybrokers installed an used VertexRSI 9.0m Earth Station Antenna at broadcast provider ViewSat at the Cobbett Hill Earth Station in Guildford in the UK

- A VertexRSI 9.0m Satellite Antenna was installed at ViewSat.

- ViewSat is located at the CBH Teleport.

- Foundation was prepared months before.

- A template was used to position the threaded rods.

- Concrete was poured.

- Foundation ready for installation.

- All antenna parts were delivered to the site.

- Assembly starts.

- All radials were installed on the antenna hub.

- Radials were numbered for correct installation.

- We had to use a crane to install the sub reflector.

- All assemblies ready for installation.

- Sub assy lifted to the main reflector.

- Sub assy installed on the main reflector.

- Antenna parts ready for lifting.

- Final adjustments to the sub.

- 16 heavy double-layer panels had to be installed

- The first panel had to be aligned properly.

- Brian was happy so far!

- Other panels followed.

- All panels installed and aligned.

- The old heater/blowers..

- ..were refurbished and checked out.

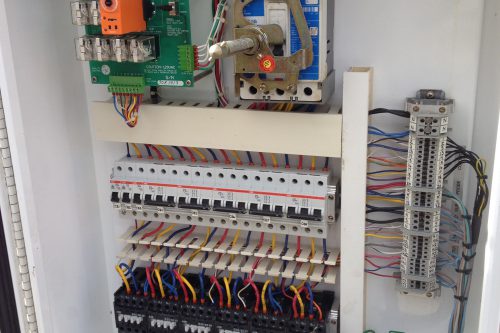

- New de-icing cabling was installed.

- De-icing enclosure panels were installed.

- De-icing enclosure panels were installed.

- De-icing enclosure panels were installed.

- All de-icing enclosure parts were painted.

- Reflector panels were sanded prior to paint.

- Reflector panels were sanded prior to paint.

- Main reflector ready for painting.

- New AZ motor installed.

- New EL motor installed.

- The de-icing cabinet was cleaned and checked out.

- The equipment shelter was lifted to the foundation.

- Foundation was made ready for the lifting operations.

- Pedestal legs were installed on the foundation.

- Next was the pedestal to be installed.

- Pedestal was leveled and ready for the main reflector.

- Main reflector was lifted.

- The reflector was prepared for installation on the Pedestal.

- Reflector was heavy due to double-layer panels.

- Main reflector installed carefully on Pedestal.

- Equipment shelter was painted.

- Reflector installed.

- Indoor tracking equipment installed.

- Antenna tested and ready for operation.

- Antenna tested and ready for operation.